Building a Conversational AI Assistant for Heavy Machinery

Modern heavy machinery is packed with features, making operation and maintenance increasingly complex. What if AI could make them easier to use? This...

4 min read

spogen.ai : December 12, 2025

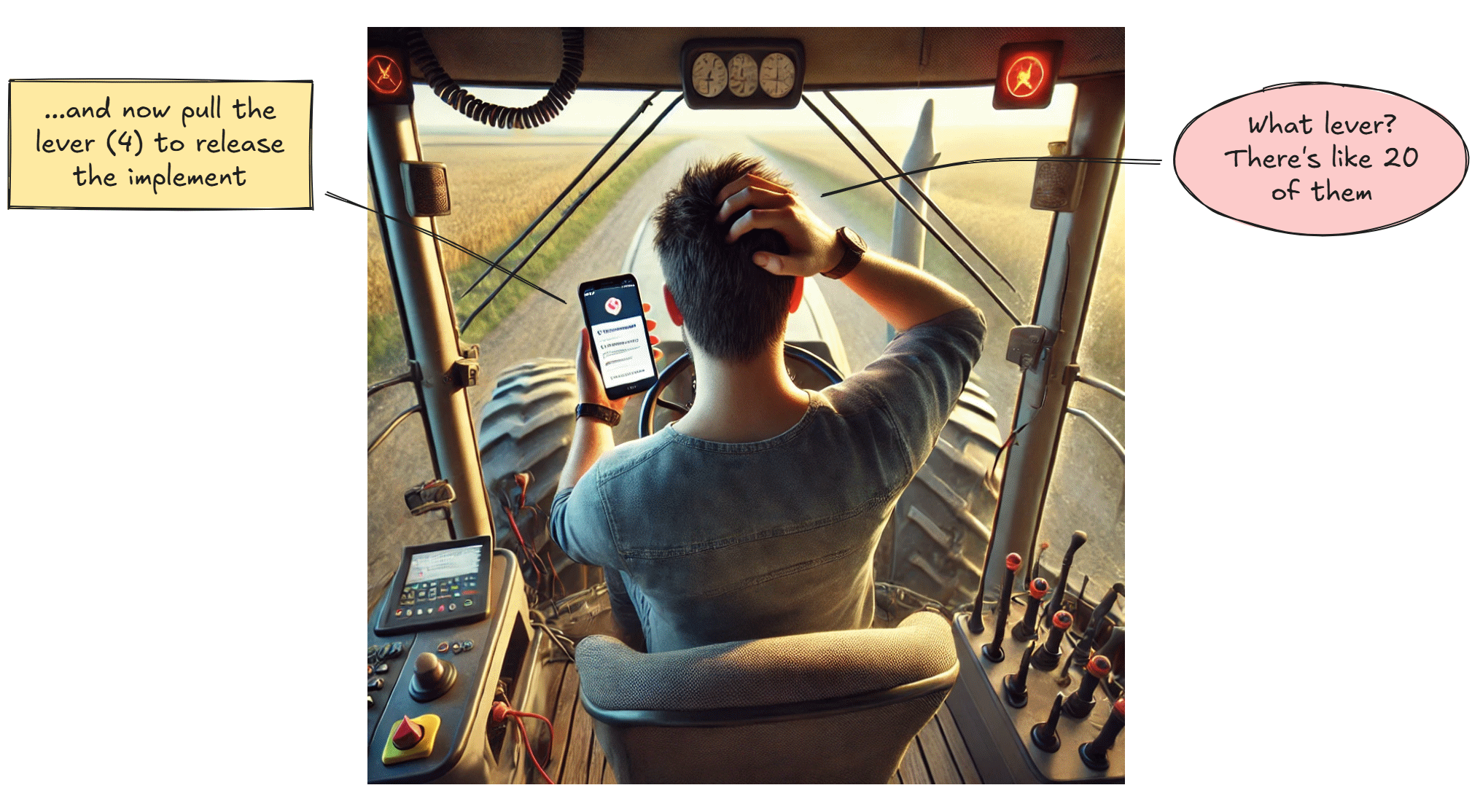

When a machine stops, whether it’s limited operator knowledge or a failure, both the operator and service centers start scrambling through binders of manuals, chase down specialists, and make urgent calls to anyone that could help. Modern machinery manuals are easily thousands of pages long, and critical instructions are often buried across PDFs, printouts and portals. When critical equipment goes down, every minute is measured in monetary losses, and missteps can erode customer loyalty.

OEMs know that improving operator support, after-sales efficiency and consistency is essential to maintaining uptime and trust. It’s a core part of the brand promise. Yet as machines become more complex and global fleets grow, internal resources are stretched thin. The conversation has shifted from “should we consider an AI assistant?” to “how do we make it happen, build it ourselves or adopt a platform?”

Complex equipment demands faster answers

Modern machines are more capable than ever. Complexity keeps increasing, but documentation is scattered and guidance often hard to access during work. Ramp-up time for new operators and technicians takes longer and longer, costing both time and money. An AI assistant that is equipped with OEM-approved sources including manuals, maintenance instructions, spare parts information, images, safety warnings and error codes can give operators a safe fix in seconds rather than hours of digging through physical guides or searching countless PDFs.

Role-based workflows across the ecosystem

OEMs aren’t looking for a chatbot. They need an industrial-grade assistant that:

spogen.ai’s Smart Assistant, for example, guides operators through safe startup, maintenance, troubleshooting steps and telemetry-based tips with voice prompts and on-screen diagrams, a daily use case that reduces the need to call support and keeps machines running through optimal use. For after-sales and fleet managers, the same platform offers analytics on common questions and gaps in documentation, helping prioritize continuous improvement. These capabilities illustrate what a purpose-built assistant must offer, but the question remains: how is this best built and maintained?

Ready platforms: fast and scalable

Productized AI assistants designed for machinery provide several advantages for OEMs evaluating time-to-value and total cost of ownership:

Building internally: underestimating the complexity

Many OEMs have tried to or are building their own assistants. Initial prototypes using generic large language models often look promising but digging deeper into data while keeping high accuracy and real-world deployments reveal persistent challenges. spogen.ai’s own experience working with OEMs highlights the key hurdles:

The result? Many projects that started as simple chatbots evolve into multi-year undertakings. Observations show that off-the-shelf solutions deliver quick wins but custom solutions require significant planning and resources. For teams under pressure to deliver measurable improvements, the timeline and uncertainty of in-house development are hard to justify.

A recent research from MIT underscores the point. The study found that 95% of generative AI pilots fail to deliver meaningful business impact. The problem isn’t the models themselves, but the gap between generic implementation and real-world workflows they’re meant to support. The report notes that companies partnering with specialized vendors succeed about twice as often as those building internally. These findings mirror our own experience: success comes from focus, execution and choosing a partner who understands your domain.

spogen.ai focuses exclusively on machinery and has distilled the lessons from multiple OEM engagements into Smart Assistant and Tech Assistant. By partnering with spogen.ai, OEMs can:

Choosing a specialized platform mitigates risk. Manual documentation and lack of real-time support make troubleshooting slower and more expensive. By turning scattered manuals and data into a unified assistant, spogen.ai helps OEMs deliver faster answers and smarter operation without drowning after-sales teams and trainers in additional tasks.

The question isn’t whether AI assistants will improve customer experience; that debate is resolved. It’s about the best path to implementation and results. Building your own assistant requires specialized AI expertise, sustained investment and long timelines without guarantees of success. Productized solutions like spogen.ai’s Smart Assistant and Tech Assistant offer speed, reliability and industry expertise that are difficult to replicate.

To decide, assess your documentation, after-sales workflows, and integration needs. To decide, assess your documentation, after-sales workflows, and integration needs. Start with a pilot on a ready platform, measure response usefulness and user satisfaction, and determine whether building an internal solution aligns with your capabilities and timelines. In most cases, working with a product partner like spogen.ai gets you there faster and with less risk than build-centric consulting, enabling your teams to focus on what they do best: designing machines that empower, not overwhelm.

What do we do in practice? Check out the Valtra Talking Tractor demo

What is this all built on? Visit our Technology-page

And click here to see our Offering.

Modern heavy machinery is packed with features, making operation and maintenance increasingly complex. What if AI could make them easier to use? This...

Whether you’re running tractors across hundreds of hectares, operating straddle carriers in a port, or managing earthmoving machines at a road...

This article is the third in our series on insights from spogen.ai’s survey of professional machinery users. In the first part, we looked at how...